Projects

Discover My Work

- Energy

- Water

- Oil and Gas

- Chemicals

- FMCG

- Environmental

- Pharmaceutical

- Minerals Processing

- Iron and Steelmaking

- Manufacturing

Electricity and VPP

A materials processing company that had deployed renewable electricity generation and energy storage infrastructure across their sites sought to maximise revenue streams through strategic operational alignment with dynamic spot electricity market pricing.

An advanced optimisation algorithm system was deployed that provided intelligent control across the entire fleet of distributed energy assets, systematically managing electricity production, storage capacity utilisation, and grid discharge flows to optimise financial returns. The algorithm incorporated sophisticated decision-making protocols based on hybrid import and export tariff structures, real-time market price signals, and operational constraints to maximise revenue generation. The optimisation system integrated predictive analytics, load forecasting capabilities, and market price modeling to enable proactive operational adjustments that capitalized on favorable electricity pricing conditions. Implementation involved comprehensive system integration with existing energy management infrastructure, development of automated control interfaces, and establishment of performance monitoring protocols to track revenue optimisation effectiveness across the asset portfolio.

Oxygen Valorisation from Electrolytic Hydrogen Production

A wastewater treatment plant strategically located adjacent to a hydrogen refueling station sought to evaluate the technical and economic benefits of using byproduct oxygen from electrolysis processes to enhance their activated sludge treatment operations.

The project objectives encompassed comprehensive assessment of oxygen byproduct value streams from electrolytic hydrogen production, advancement of technology and commercial readiness for oxygen offtake systems, and identification of synergistic opportunities to reduce barriers to renewable hydrogen adoption through innovative collaboration between hydrogen producers and wastewater treatment facilities. A feasibility study incorporating systematic concept design development was undertaken to determine optimal process parameters, oxygen transfer efficiency requirements, and physical infrastructure configuration for oxygen integration into existing activated sludge systems. The technical analysis included evaluation of dissolved oxygen control strategies, aeration system modifications, and process optimisation protocols to maximise treatment efficiency while using high purity oxygen. High-level economic assessment incorporated capital cost analysis for oxygen transfer infrastructure, operational cost savings from reduced conventional aeration requirements, and deferred capital investment through capacity increases. The study identified critical conditions and operational constraints for oxygen enrichment implementation in wastewater treatment applications, including safety considerations, process control requirements, and regulatory compliance factors. The project methodology explored scalability and replicability potential across other wastewater treatment facilities.

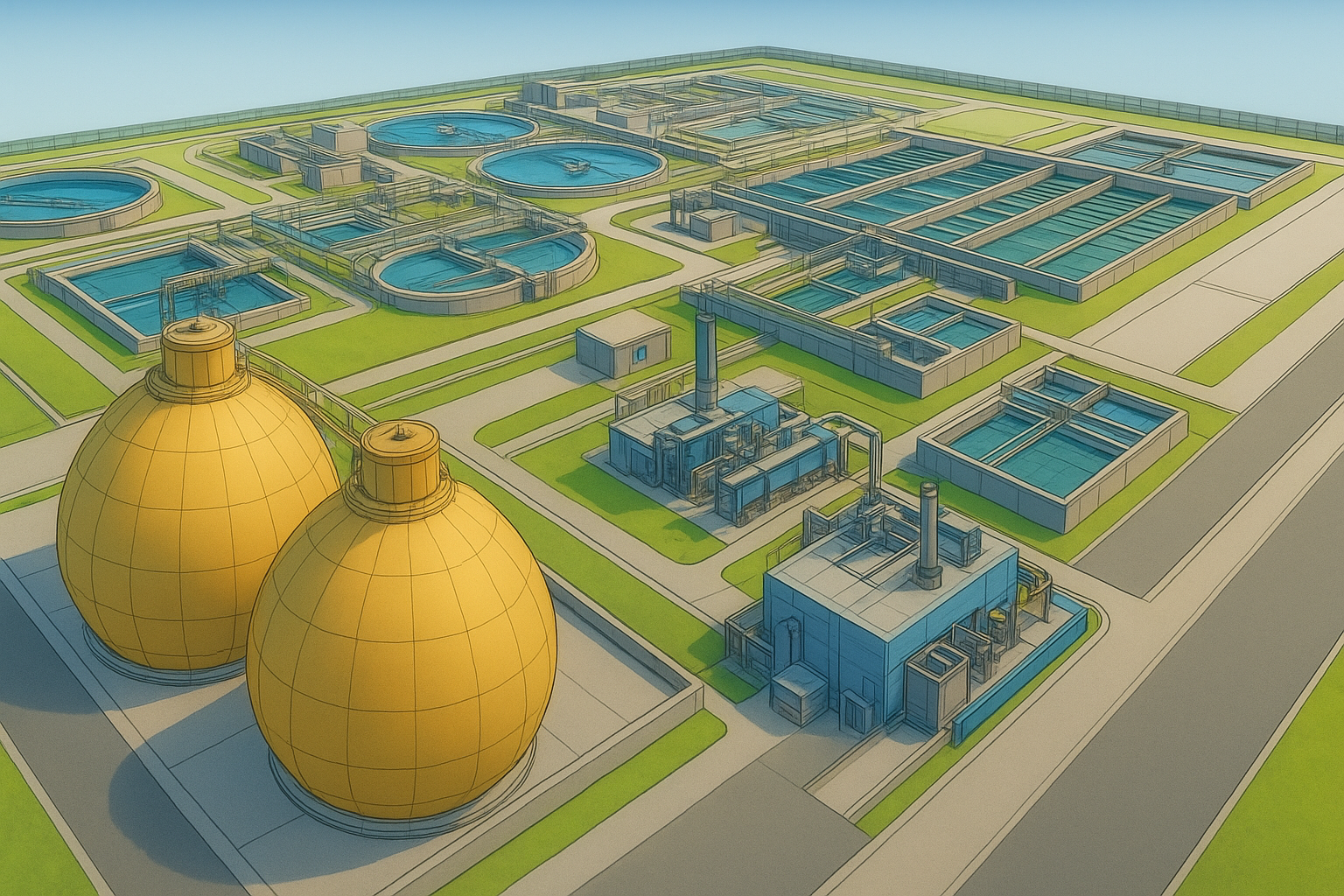

Wastewater Treatment Plant Upgrade

A municipal wastewater treatment plant had exceeded its operational capacity and required a major infrastructure upgrade to accommodate future demand while achieving enhanced effluent quality standards for environmental compliance.

In the role of Principal’s project manager and contract Superintendent, I led the systematic development and execution of this complex infrastructure project over a 3-year timeline. The project methodology encompassed initial market engagement through expressions of interest, followed by early contractor involvement (ECI) processes to leverage industry expertise during conceptual development phases. This approach facilitated collaborative contract negotiation, comprehensive technical scope definition, and detailed specifications development aligned with regulatory requirements and operational objectives. The methodology integrated systematic design management protocols, construction oversight procedures, and structured commissioning processes to ensure seamless project delivery. The systematic approach culminated in successful handover of the upgraded treatment facility, which now provides adequate capacity for projected population growth within the catchment area while delivering substantially improved effluent quality that exceeds discharge requirements for local waterway protection. The project methodology demonstrated effective integration of technical engineering solutions with project management best practices to achieve both immediate operational improvements and long-term infrastructure sustainability.

Wastewater Treatment MBBR Carrier Degradation

A wastewater treatment plant was experiencing fractured Moving Bed Biofilm Reactor (MBBR) carriers bypassing internal screening mechanisms and appearing downstream, despite retention screens within the bioreactor. The water utility needed to understand why and what could be done to reduce this occurrence.

In the absence of established industry protocols for quantifying MBBR carrier degradation, an innovative laboratory-scale testing methodology was developed using a precision drum tumbler system with specialised abrasive media originally designed for gemstone polishing. This novel approach replicated complex mechanical stresses experienced by carriers under full-scale operational conditions in both mixed and aerated environments, while achieving accelerated degradation timelines. The methodology underwent rigorous optimisation through systematic experimental investigation of various configurations and testing parameters. Post-testing analysis involved gravimetric determination of mass loss percentages for carriers exhibiting wear patterns enabling passage through existing screening infrastructure. Laboratory-derived degradation data was correlated with empirical observations from full-scale operations to establish predictive relationships. Following successful validation of the laboratory-to-full-scale correlation, the methodology was applied to evaluate alternative MBBR carrier materials, enabling accurate forecasting of operational lifespan and quantification of anticipated material losses under site-specific conditions.

Wastewater Treatment Capacity

A water utility wanted to understand the limits of a potential capacity upgrade for a wastewater treatment plant that incorporated a central biosolids processing facility, which also received imported biosolids from surrounding plants. The challenge was not only to accommodate increased throughput but also to evaluate the knock-on effects across other nearby treatment plants to optimise operations and transport.

A customised parametric design tool was developed and applied to optimise the process configuration for the upgraded facility. Beyond spatial layout, the tool embedded process engineering analysis, accounting for mass and energy balances, solids retention times, aeration demands, and sludge dewatering performance. Multiple design scenarios were systematically generated and assessed, with each scenario tested against site constraints, process performance criteria, and regulatory compliance requirements. Sensitivity analyses were also performed to identify process bottlenecks and define the critical parameters that would ultimately limit capacity.

This integrated approach ensured that the evaluation went beyond layout feasibility to provide a technically rigorous assessment of process robustness and scalability. The outcomes of the work delivered a validated framework for long-term capacity planning, enabling the utility to quantify future expansion limits, optimise equipment utilisation, identify process risk points, and strategically align capital investment with projected demand growth.

Production Loss Reporting

A coal seam gas producer required a reporting tool to systematically quantify production losses and equipment availability metrics across multiple criteria including asset type and functional area classifications.

A detailed information process map that systematically modelled the complex business processes governing information acquisition, processing, and distribution throughout the organisation was developed, accounting for the extensive array of heterogeneous equipment types and diverse real-time data sources. Following process mapping completion, structured requirements engineering techniques were used to define detailed system specifications, incorporating functional requirements, performance criteria, and integration parameters. The design phase utilised systematic engineering approaches including modular architecture development, database schema optimisation, and user interface design principles tailored to operational workflows. Development methodology followed iterative engineering practices with version control systems to ensure code quality and traceability. Extensive testing methodology encompassed unit testing, integration testing, user acceptance testing, and performance validation under simulated operational conditions to ensure reliable production loss quantification and equipment availability reporting.

Gas Field Development

A coal seam gas producer developing a new gas field required engineering design and implementation of an underground piping network and associated gas dewatering facilities to optimise production efficiency and environmental compliance.

The gas field design incorporated a sophisticated underground HDPE piping system for the gas gathering network, featuring strategically positioned high point vents for gas release and low point drains at engineered locations to prevent liquid accumulation and maintain optimal flow characteristics. Co-produced water separated at individual wellheads was systematically collected through a parallel underground HDPE piping infrastructure for reliable transport to centralised collection dams and evaporation ponds. Specialised fast fusion welding machines were employed on extended piping runs prior to installation in excavated trenches, delivering significant time and cost efficiencies. Prior to connection with the central gas compression facility, an engineered underground low-pressure separation vessel was installed to provide additional water separation capacity and ensure gas quality specifications. Commissioning of the buried gathering system was executed through rigorous pneumatic testing protocols adhering to stringent safety standards, with measurement and analysis of leakage rates during pressure testing evaluated against predetermined acceptance criteria to ensure system integrity and operational reliability.

Shift Production Reports

A coal seam gas producer sought to transition from their existing manual, unstructured shift logging practices to a centralized electronic reporting system that would capture production operator data in a standardized, searchable format.

An extensive digital shift reporting platform was designed that integrated seamlessly with existing operational workflows while ensuring data consistency and accessibility across all production shifts. The system architecture incorporated user-friendly interfaces optimised for field operators, automated data validation protocols to ensure completeness and accuracy, and robust database management capabilities for efficient storage and retrieval of operational information. Key engineering considerations included implementing secure cloud-based data synchronisation to enable real-time reporting from multiple sites, and creating reports that captured critical operational parameters, equipment status, safety observations, and production metrics. The platform featured advanced search functionality with filtering capabilities, automated alert systems for critical incidents, and comprehensive reporting dashboards that provided management with actionable insights into operational trends and performance indicators.

Plant Modification & Change Management System

For a major chemical manufacturer, a structured system was developed to manage plant modifications and ensure safe, compliant change management. The system provided a clear, step-by-step framework to evaluate and control risks associated with equipment, process, and procedural changes. Each change request included:

Formal submission and approval capturing scope, justification, and potential impacts.

Risk evaluation to determine the extent of process safety studies required (e.g. HAZOP, risk assessments, or focused reviews).

Information management checks to assess what data, drawings, and records needed to be updated as a result of the modification.

Defined responsibilities and workflows across engineering, operations, and safety teams.

Action tracking and close-out to ensure all design checks, training, documentation updates, and regulatory requirements were completed.

Audit and review features to provide assurance that modifications were executed safely and lessons learned were captured.

This tailored system gave the client confidence that every modification, from minor equipment changes to major process upgrades, was properly reviewed, authorised, and documented. It not only improved safety and compliance but also strengthened the integrity of operational records and reduced long-term risk.

Revitalisation Strategy for Legacy Urea Manufacturing Plant

A strategic revitalisation was launched at a urea manufacturing facility built in the 1960s, which had suffered from years of underinvestment and declining operational standards. The initiative aimed to restore performance, attract investment, and re-engage the workforce.

A series of targeted improvement projects were defined as part of the strategy. Each project was assigned to a project manager selected from the existing operations and maintenance teams, fostering ownership and accountability. These projects addressed key production bottlenecks, equipment reliability, and product quality, and team management.

To support coordination and transparency, a custom database application was developed to track project progress. This tool became central to weekly review meetings, enabling real-time updates, milestone tracking, and issue resolution. The structured approach helped maintain momentum and ensured alignment across departments.

The strategy delivered measurable results. Production increased by nearly 10%, driven by improved throughput and reduced downtime. Product quality stabilised, with tighter control over granule size distribution. Staff engagement also improved, with clearer goals and visible progress contributing to a renewed sense of purpose.

This project demonstrates the impact of combining technical insight with structured project management and team empowerment, especially in legacy industrial environments.

Food Processing Production Line

A bulk herb processing company sought to enhance operational efficiency through increased throughput, improved product quality, and minimised spillage and waste generation.

Operating within severe spatial constraints that precluded significant structural modifications, a facility analysis was conducted to identify production bottlenecks, quantify spillage sources, and assess contamination risks while evaluating innovative equipment alternatives. Through iterative design optimisation and extensive operator collaboration, a breakthrough concept was developed that maximised existing infrastructure utilisation. Recognising the specialised nature of herb processing requirements, a critical separation machine was completely re-engineered, incorporating novel design principles and custom-built components validated through rigorous pilot-scale trials and extensive test protocols. Maintaining precise operational control was paramount to ensure consistent feed rates into downstream processes. To address this challenge, an innovative bespoke production line simulation system integrated with an advanced throughput control algorithm was developed, incorporating real-time monitoring and automated adjustment capabilities. The simulation platform underwent detailed validation testing to demonstrate effectiveness under varying operational scenarios. The engineered solution was successfully installed and commissioned, achieving all project objectives while delivering exceptional operational performance and gaining enthusiastic acceptance from facility operators, demonstrating the successful integration of innovative engineering solutions within existing infrastructure constraints.

Lean Manufacturing: Line Reconfiguration

A food manufacturer sought to reconfigure their production line to implement lean manufacturing principles while enhancing employee health and safety standards.

The project was initiated through value stream mapping and detailed workflow analysis to identify inefficiencies, waste sources, and safety hazards within the existing production configuration. The engineering methodology involved systematic application of lean principles including 5S workplace organization, standardized work procedures, and continuous flow optimization. Detailed facility layout redesign was conducted using computer-aided design tools and ergonomic analysis software to optimise material flow patterns, reduce transportation waste, and eliminate non-value-added activities. Safety engineering assessments incorporated hazard identification and implementation of engineering controls to mitigate workplace injuries. The project execution involved phased implementation planning to minimise production disruption, with detailed project scheduling coordinating equipment relocation, utility modifications, and employee training programs. Deliverables also included new standard operating procedures, visual management systems, and performance monitoring protocols to sustain lean improvements. Quality assurance measures ensured compliance with food safety regulations throughout the reconfiguration process. The systematic engineering approach successfully delivered improved production efficiency, reduced cycle times, enhanced product quality consistency, and significantly improved workplace safety conditions through elimination of ergonomic hazards and implementation of safety-by-design principles.

Food Processing Finished Goods Warehouse

A food products manufacturing company sought to establish an expanded finished goods warehouse and product selection facility to accommodate growing production volumes and enhance distribution efficiency.

After conducting a site analysis to determine optimal facility sizing, layout configuration, and operational workflow design, the project encompassed engineering design for a warehouse facility, incorporating specialised requirements for food-grade storage environments including temperature control systems, humidity management, and contamination prevention protocols. The engineering scope included utility infrastructure design encompassing electrical distribution systems, HVAC systems optimised for food storage requirements, and fire suppression systems compliant with safety standards. Project management activities coordinated multi-disciplinary teams, regulatory approval processes, and construction scheduling to minimise operational disruption. Construction oversight ensured compliance with food safety regulations, structural integrity requirements, and operational commissioning protocols to deliver a fully integrated facility meeting expanded capacity objectives and enhanced operational efficiency standards.

Beverages Production Hygiene Improvements

The production area surrounding the maturation tanks at a beer production facility had deteriorated significantly, presenting substantial risks of hygiene contamination and regulatory non-compliance that threatened product quality and safety standards.

Extensive site remediation engineering was undertaken to restore the facility to food-grade manufacturing standards through systematic infrastructure rehabilitation and hygienic design implementation. The engineering scope encompassed extensive refurbishment of building envelope systems, including complete removal and replacement of deteriorated flooring with seamless, chemical-resistant tile systems designed for washdown operations and microbial control. Wall surface remediation involved installation of hygienic tile cladding systems to eliminate potential contamination harbouring points. Process piping infrastructure was rehabilitated, incorporating food-grade materials, sanitary welding techniques, and proper drainage configurations to prevent bacterial growth and facilitate cleaning protocols. Thermal insulation systems were completely re-engineered using hygienic lagging materials and vapor barrier systems compliant with food safety regulations. Extensive stainless steel cladding installation provided corrosion-resistant surfaces with smooth, cleanable finishes throughout critical production zones.

Brewery Kegging Operation Reconfiguration

A major brewer operating multiple satellite sites sought to consolidate its operations into the main production facility. One of these satellite sites was responsible for processing returned beer that was deemed unfit for sale. This required kegs of unsuitable beer to be emptied in a controlled manner, with precise measurement of volumes to meet customs and excise requirements.

Prior to the relocation of this function, the existing operations was analysed to identify opportunities for improved efficiency. This review considered both reconfiguration of existing practices and the application of new technologies. A central feature of the new design was a pneumatic system capable of rapidly and safely emptying individual kegs. The discharged beer was directed to a large stainless-steel tank mounted on load cells, providing accurate mass measurement of the returned alcohol. This enabled the brewer to reliably deduct the associated excise duty, ensuring regulatory compliance and cost recovery.

To further optimise performance, an automated anti-foam dosing system was integrated, with chemical dosing controlled in proportion to the mass flow rate of beer being discharged. This eliminated issues with excessive foaming, improved reliability, and ensured smooth continuous operation.

Through this consolidation and process redesign, the brewery not only achieved its goal of centralising operations but also realised significant gains in production throughput. The improved process layout and enhanced technologies delivered measurable efficiency improvements, strengthening both operational performance and long-term compliance assurance.

Brewery Heating Efficiency

A brewer experienced unexplained capacity reduction in their kettle heating system, requiring detailed process engineering investigation to identify the root cause of thermal performance degradation.

Systematic diagnostic analysis was conducted beginning with heat and mass balance calculations across the heating system to quantify energy transfer inefficiencies and identify performance deviations from design specifications. The investigation methodology incorporated thermal analysis of heat exchanger performance, steam distribution network evaluation, and condensate return system assessment. Through process engineering calculations and field measurements, a degraded heat transfer coefficient was identified as causing a significant performance degradation in the steam condenser unit. Process diagnostics revealed that accumulation of non-condensable gases within the condenser was creating thermal resistance and reducing effective heat transfer surface area available for condensation. The systematic process engineering approach successfully identified the steam condenser effectiveness as the primary root cause, where non-condensable gas buildup had significantly compromised heat transfer performance and reduced overall kettle heating capacity.

Consumer Product Development

A paint manufacturer wanted to develop an innovative plastic packaging system specifically engineered to enhance consumer usability while meeting stringent performance requirements.

The project initiated with systematic translation of end-user requirements into detailed functional specifications, incorporating rigorous test methodologies and quantitative acceptance criteria to ensure customer satisfaction. Following development of injection moulded prototype containers filled by the client, the innovative approach included palletised transport testing under simulated distribution conditions. These systematic trials revealed a critical resonance phenomenon occurring in stacked container configurations that resulted in dynamic column instability, threatening product integrity during transportation. Laboratory-based vibration analysis using sophisticated frequency response measurement equipment verified the resonance characteristics, enabling precise correlation with real-world transport conditions and loading scenarios. Advanced finite element analysis was subsequently applied to evaluate structural performance parameters and determine optimal design modifications to effectively mitigate resonance effects while improving overall stability performance. To support production planning and ensure manufacturing feasibility, discrete event simulation modelling of the complete container manufacturing line was conducted using advanced process optimization software. This detailed analysis established optimal process configuration parameters, identified potential bottlenecks, and validated throughput performance capabilities prior to committing resources to detailed factory layout design and capital equipment procurement.

High Speed Palletiser

An injection moulding company manufacturing high-volume consumer products required an automatic palletiser to manage a challenging container geometry and improve overall productivity.

The project began with the development of a detailed functional specification that translated the client’s operational requirements into clear performance, safety, and integration criteria. Engineering analysis was undertaken to assess handling dynamics, pallet stability, and throughput rates. A robotics supplier was then engaged to design and build a bespoke palletiser solution, with close technical oversight maintained throughout the design and fabrication phases.

Given the limited floor space within the existing factory, project management played a critical role in coordinating layout optimisation, interface with existing production lines, and staged installation planning to minimise disruption to operations. The system was successfully installed and commissioned, delivering reliable automated palletising within the constrained footprint and achieving the targeted gains in efficiency and throughput.

Wastewater and Environment Microplastics

A water utility required quantification of microplastic contamination across multiple wastewater treatment plant process streams and surrounding environmental matrices, including marine organisms in proximity to effluent discharge locations.

A systematic sampling and analysis plan was developed through collaborative stakeholder engagement, incorporating regulatory requirements, analytical protocols, and quality assurance measures to ensure data reliability and regulatory compliance. The methodology involved strategic sampling point selection across wastewater process streams including primary clarifiers, secondary treatment systems, and final effluent, with concurrent collection of biosolids. Advanced analytical procedures were implemented for microplastic identification and characterization, using Fourier Transform Infrared Spectroscopy (FTIR) to determine polymer type. Morphological classification included shape and size distribution, and color analysis for source identification. Environmental sampling protocols encompassed water column sampling, sediment collection, and biota sampling from marine organisms at strategic locations surrounding treatment plant outfalls to assess environmental impact and bioaccumulation patterns. Laboratory analysis incorporated standardised microplastic extraction techniques, quality control measures, and statistical analysis to quantify contamination levels and characterize particle properties. Data analysis involved comprehensive evaluation to identify microplastic sources, assess environmental impact pathways, and quantify discharge loading rates.

Coal Seam Gas Water Beneficial Reuse

A coal seam gas producer sought to transform their waste co-produced water, characterised by elevated concentrations of dissolved salts and sodium compounds, into a viable resource for agricultural irrigation.

A process was developed for the treatment of co-produced water, specifically targeting the reduction of sodium concentrations to mitigate soil impact and enable its reuse for irrigation. Containerised treatment units were engineered, fabricated, and commissioned on site, delivering a turnkey solution that converted a previously waste stream into a reliable source of agricultural water.

The challenge required addressing complex water chemistry issues where the high sodium concentration would otherwise render the water unsuitable for crop production. An innovative multi-stage treatment process was developed that incorporated ion exchange technologies and chemical precipitation to achieve precise control over dissolved salt concentrations. Custom-engineered containerised treatment units were designed to accommodate varying flow rates and feed water compositions. Commissioning procedures included water quality testing, process optimisation under site-specific conditions, and validation of treatment efficacy against agricultural water quality standards. The turnkey solution successfully converted a previously problematic waste stream into a dependable source of irrigation water through innovative engineering applications.

Specialised Piping and Heat Exchanger Replacement

A bulk pharmaceuticals manufacturer experienced significant wear and deterioration in their Hastelloy piping system and graphite block heat exchanger blocks, requiring thorough project management to replace the equipment without operational interruption.

The project coordinated multi-disciplinary teams including materials specialists, process engineers, and maintenance personnel to develop a remediation strategy. The project scope included development of condition monitoring systems, and replacement scheduling to minimise future operational disruptions. Project execution involved phased implementation planning to maintain production continuity, with detailed scheduling of equipment shutdowns, material procurement, and installation activities. Project controls monitored progress against budget and timeline objectives, while quality assurance protocols ensured compliance with pharmaceutical manufacturing standards throughout the remediation process. The systematic project management approach successfully coordinated resource allocation, vendor management, and stakeholder communication to deliver effective system rehabilitation while maintaining operational requirements and regulatory compliance standards.

Vessel Flame Arrestors

A pharmaceutical manufacturer engaged my expertise to upgrade flame arrestors on several process vessels as part of a broader safety and compliance initiative. The existing units were outdated and no longer met current standards for flammable vapour containment and explosion risk mitigation.

The project began with a detailed assessment of the equipment and process conditions. Suitable replacement flame arrestors were selected based on vessel specifications, venting requirements, and compatibility with pharmaceutical-grade materials. Technical guidance was provided throughout the selection and installation phases to ensure the new units met both regulatory and operational expectations.

Collaboration with the client’s engineering and safety teams helped streamline implementation. Installation was carefully staged to minimise disruption to production, and updated documentation including risk assessments and validation reports was delivered to support ongoing compliance.

The upgraded flame arrestors significantly improved safety performance and reduced ignition-related risks. The project aligned the facility with current standards and reinforced a proactive approach to process safety.

This work demonstrates my practical, standards-driven approach to engineering in regulated environments with a strong focus on safety, reliability, and continuity of operations.

Coal Processing Plant Shutdown Planning

A coal processing plant situated in a remote Indonesian location required project management to execute their major repair and refurbishment program while minimising operational disruptions to production schedules.

The project involved developing planning frameworks with detailed Gantt chart scheduling and resource allocation strategies to optimise workflow coordination and timeline management. The project presented significant logistical challenges due to the remote geographical location, requiring specialised procurement planning and supply chain management to address extended lead times for critical equipment components, replacement parts, and skilled labour. A particular project management challenge involved managing uncertainty regarding equipment condition assessments, as the full scope of refurbishment requirements could only be determined following systematic equipment dismantling and inspection procedures. The project methodology incorporated contingency planning protocols, flexible scheduling frameworks, and adaptive resource management to accommodate scope changes discovered during the dismantling phase. Project execution involved coordinating multiple work streams simultaneously, managing specialised contractor teams, and implementing risk mitigation strategies to address potential delays in equipment delivery to the remote site. Advanced project controls included regular progress monitoring, critical path analysis, and stakeholder communication protocols to ensure alignment between operational requirements and project objectives. The systematic project management approach successfully delivered the refurbishment program while maintaining flexibility to accommodate evolving project scope and equipment replacement requirements.

Blast Furnace Heating Control

An integrated iron and steelworks operating blast furnaces relied on large refractory-lined regenerative heat exchangers, known as stoves, to preheat the hot blast air before it was introduced near the base of the furnace through the tuyeres. To enhance overall furnace performance, the operator sought to improve heating efficiency by implementing more advanced control of the stove heating cycles and rates.

A first-principles computer simulation model was developed from the ground up to accurately represent the complex thermofluid processes within the regenerative heat exchangers. The model incorporated detailed fluid dynamics, combustion kinetics, and transient heat transfer mechanisms occurring within the refractory lining and gas flows. This provided a robust digital environment for testing and optimisation.

Building on this foundation, a model-based predictive control (MPC) strategy was designed. The control system utilised real-time state variables from the operating process to forecast system conditions over defined future time horizons. Multiple heating and valve sequencing scenarios were automatically evaluated by the algorithm, with the control logic selecting the optimal approach to maximise efficiency while maintaining operational and safety constraints.

The simulation environment also included a dynamic visual interface, enabling operators to view predicted temperature distributions, combustion behaviour, and other critical process parameters within the stoves. Key efficiency indicators and control recommendations were reported in real time, providing operators with actionable guidance to improve fuel utilisation, stabilise blast furnace operations, and achieve measurable gains in energy efficiency.

AS4024 Machinery Compliance

Working closely with a wastewater equipment manufacturer, a robust assessment of their imported and fabricated machinery to the requirements of AS4024, the Australian standard for the safety of machinery, was completed. The project involved a detailed compliance review across several product lines, focusing on mechanical safety, guarding, emergency stop systems, and control interface design.

The first step was to conduct a comprehensive risk assessment, identifying potential hazards associated with machine operation, maintenance, and access. The existing safety measures were reviewed against AS4024 requirements, highlighting areas that required modification or improvement. This included evaluating fixed and interlocked guards, verifying the adequacy of emergency stop functions, and assessing the safety-related parts of control systems.

I collaborated directly with the manufacturer’s design and engineering teams to implement practical, cost-effective solutions. These included redesigning access panels to eliminate crush points, integrating compliant interlock systems, and updating wiring and control schematics to meet functional safety standards. I also supported the development of updated technical documentation, including risk assessments, safety validation reports, and user manuals.

The result was a fully compliant suite of equipment, ready for safe deployment in industrial wastewater treatment facilities across Australia. Beyond compliance, the project helped the client improve the overall safety culture within their organisation and provided a clear framework for future product development.

This project reflects my hands-on approach to safety engineering, balancing regulatory compliance with real-world practicality, and my commitment to delivering solutions that protect both people and productivity.